Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

PPS GF35 MF30 TPS80R76N

Glass Filled: 35%

Mineral Filled: 30%

(Custom materials available according to your Technical Data Sheet)

- Les détails du produit

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

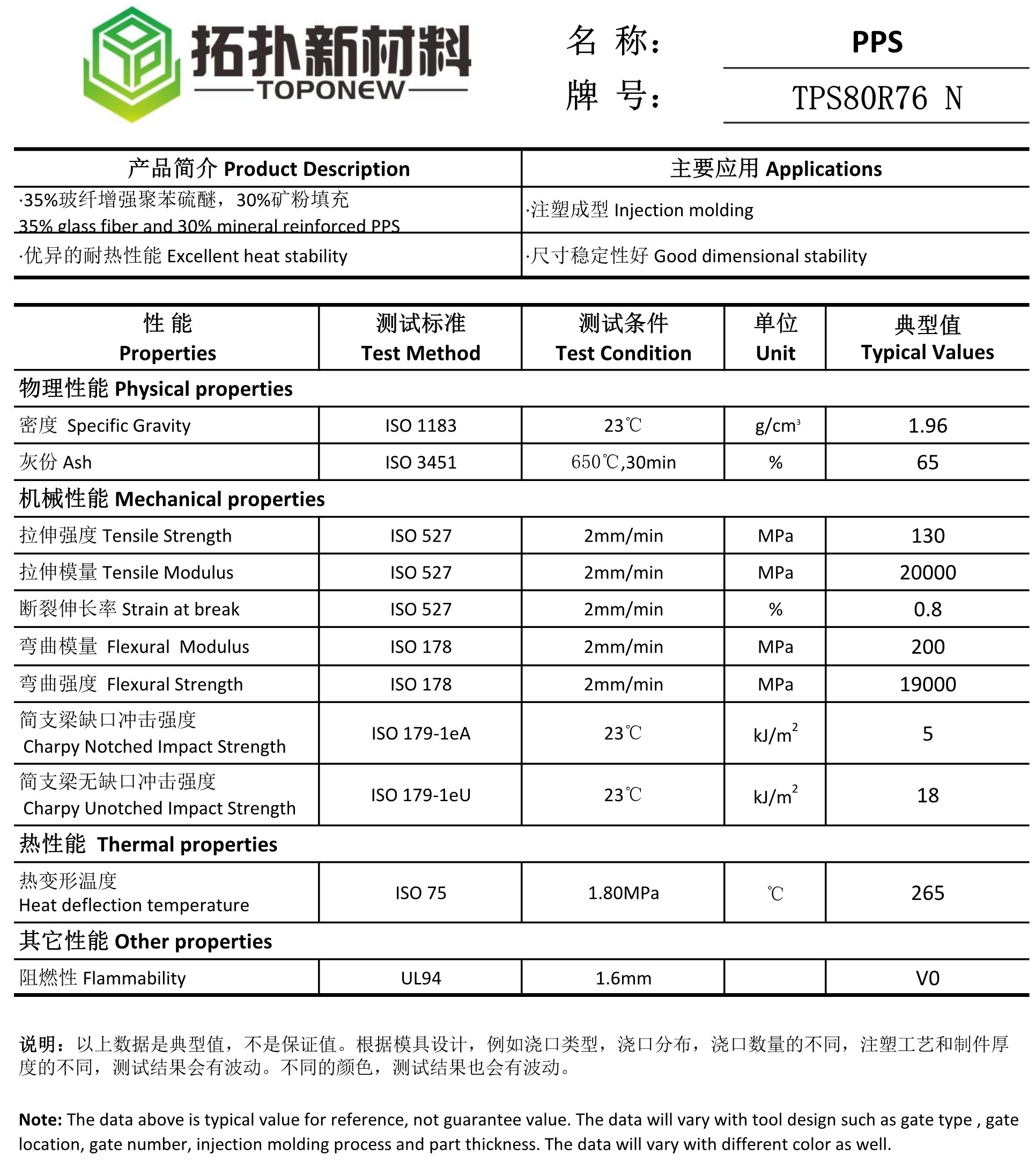

Technical Data Sheet of PPS GF35 MF30 TPS80R76N PPS

PPS GF35 MF30 TPS80R76N. This modified Polyphenylene Sulfide material is specifically engineered with 35% glass fiber and 30% mineral filled content, making it an ideal choice for various applications.

Compliant with RoHS environmental requirements, our PPS GF35 MF30 TPS80R76N is tailored for injection molding, offering superior heat resistance and excellent dimensional stability. Its remarkable resistance to creep ensures the product's longevity, while its exceptional chemical resistance safeguards against corrosion. Additionally, its fire-retardant properties ensure enhanced safety for various applications.

The outstanding electrical insulation performance of PPS GF35 MF30 TPS80R76N makes it well-suited for applications in the chemical industry, electronics and electrical appliances, low-voltage electrical systems, machinery, and more. One common application is in MCB operating mechanisms, where our material provides durability and reliability.

Available in natural and black color options, our PPS GF35 MF30 TPS80R76N offers versatility in design and manufacturing. Its ease of formability makes it a favored choice among engineers and manufacturers alike.

Choose TOPONEW's PPS GF35 MF30 TPS80R76N for your modified plastic needs and experience the excellence and reliability that our products provide. Contact us today to learn more or to place an order.

Q & A

1.Advantage of GF and MF plastic material

GF (Glass Fiber) and MF (Mineral Filled) are two types of plastic material additives that offer several advantages when incorporated into a polymer matrix:

Increased Strength and Stiffness: Adding GF or MF to the plastic enhances its mechanical properties, making it stronger and stiffer. This is especially beneficial for applications that require structural integrity and dimensional stability.

Improved Heat Resistance: GF and MF additives help improve the plastic's ability to withstand high temperatures without deformation or loss of mechanical properties. This makes them suitable for use in environments with elevated temperatures, such as automotive under-the-hood applications.

Enhanced Dimensional Stability: GF and MF additives reduce the shrinkage and warpage tendency of plastic during the cooling process. This results in improved dimensional stability, making it easier to maintain tight tolerances and ensuring a more consistent final product.

Increased Impact Resistance: The incorporation of GF or MF into the plastic matrix enhances its impact resistance, making it less prone to cracking or breaking under stress. This is valuable for applications that require durability and resistance to impacts, such as automotive components or electronic enclosures.

Improved Chemical Resistance: GF and MF additives can enhance the chemical resistance of plastic materials, making them more resistant to corrosion, solvents, and other harsh chemicals. This is particularly important in industries such as chemical processing or oil and gas, where exposure to corrosive substances is common.

Fire Retardance: GF and MF additives can improve the flammability characteristics of plastic, making it more resistant to ignition and reducing the rate of flame propagation. This makes them suitable for applications where fire safety is crucial, such as electrical components or building materials.

Cost Savings: Incorporating GF or MF additives into plastic can lead to cost savings by reducing material usage. The increased strength and stiffness provided by these additives allow for the production of thinner-walled parts without sacrificing performance, resulting in overall material savings.

Overall, GF and MF plastic materials provide a wide range of benefits, including increased strength, improved heat resistance, enhanced dimensional stability, improved impact resistance, enhanced chemical resistance, fire retardance, and cost savings. These advantages make them valuable options for a variety of industries and applications.

PPS stands for Polyphenylene Sulfide. It is a high-performance engineering thermoplastic known for its excellent chemical resistance, heat resistance, flame retardancy, and dimensional stability. PPS is a semi-crystalline polymer that can retain its mechanical properties at high temperatures, making it suitable for demanding applications in various industries.

Some key characteristics of PPS material include:

- High Heat Resistance: PPS can withstand high temperatures without significant loss of properties, making it suitable for applications requiring thermal stability.

- Chemical Resistance: PPS is resistant to a wide range of chemicals, acids, and bases, making it suitable for harsh chemical environments.

- Flame Retardant Properties: PPS is inherently flame retardant, which enhances its safety in applications where fire resistance is essential.

- Dimensional Stability: PPS exhibits low moisture absorption and excellent dimensional stability, making it suitable for parts requiring tight tolerances.

PPS is commonly used in industries such as automotive, electrical and electronics, aerospace, and industrial applications where high performance and reliability are required.

Download

-

PPS TPS80R76N(1).pdf

Download PPS TPS80R76N(1).pdf